Mitsubishi GX-F Advanced Fiber Laser

Artificial Intelligence (AI) Technology at its Best

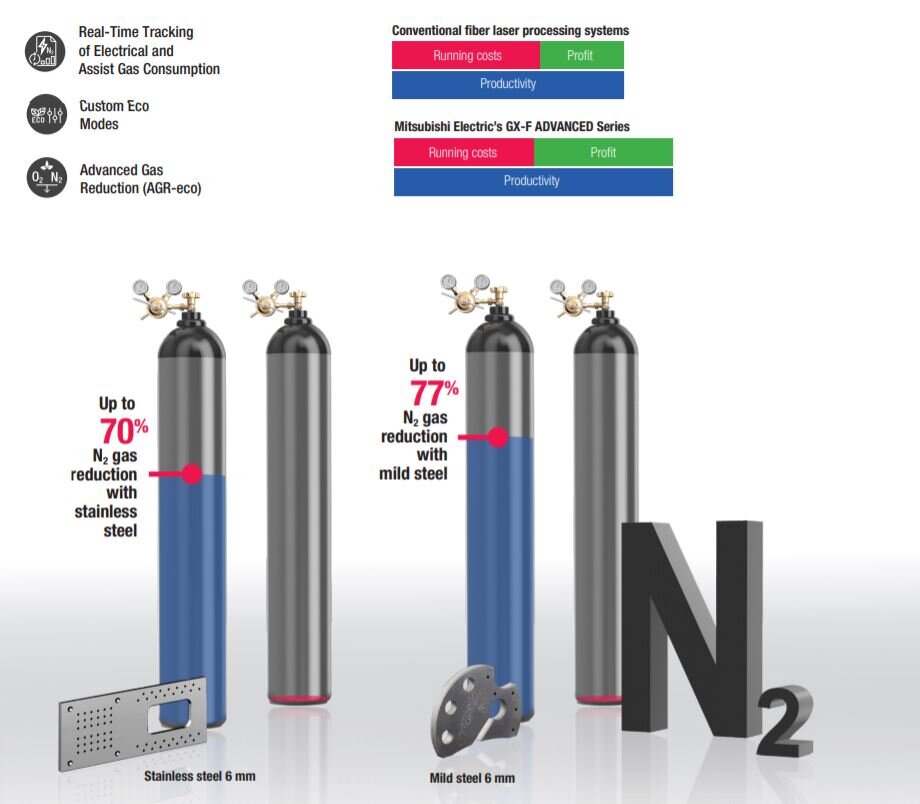

With the latest in artificial intelligence (AI) and gas reduction technology, the new GX-F ADVANCED Series of two-dimensional fiber lasers delivers more power while using less nitrogen.

Artifical Intelligence enables the fiber laser to teach itself. Using machine learning and the many sensors on the machine, the software recognizes what data helps it optimize performance, and makes adjustments. This is all done without human intervention - so it continues to get better.

Specially designed and built by Mitsubishi, the GX-F ADVANCED Series is one of the only laser systems in the industry with a single source for both service and support.

ECO-Friendly and lower operating costs

Mitsubishi Electric’s original AGR-eco technology can decrease nitrogen consumption by up to 77 percent. The GX-F ADVANCED Series performs real-time electrical and assist gas consumption monitoring. Not only that, since nozzles don’t come into contact with the material, consumables last longer.

Features:

Advanced artificial intelligence technology

Mitsubishi-designed automated zoom head

Nozzle changer

AI-assisted cutting

Augmented reality with drop and cut, part rotation, and rectangular nesting

Visible Processing Status (VPS)

Advanced Gas Reduction (AGR-eco)

Dynamic Drive Control (DDC)

Dross Reduction Control (DRC)

Plasma Guard Control (PGC)

High Peak Piercing (HPP)

Mel’s Eye (Plasma, Burn and Burst Detection)

Protective Process Window Monitoring

LOWER OPERATING COSTS MEAN HIGHER PROFITS

Mitsubishi Electric’s original AGR-eco technology can decrease nitrogen consumption by up to 77 percent. The GX-F ADVANCED Series performs real-time electrical and assist gas consumption monitoring. Not only that, since nozzles don’t come into contact with the material, consumables last longer. As a result:

• No scratches on the material surface • Working material thickness can range from 1/16” to 1”.

Machine Specs

| Available Platform | ML 3015 GX-F ADVANCED | ML 4020 GX-F ADVANCED |

| Machine Structure | Weld Bonded Chassis with Precision Helical Rack & Pinion, Direct Drives | |

| X – Axis Stroke | 122.0” (3100mm) | 161.41” (4100mm) |

| Y – Axis Stroke | 61.61” (1565mm) | 82.67” (2100mm) |

| Z – Axis Stroke | 4.72” (120mm) | 4.7” (120mm) |

| Maximum Work Piece Size | 120.1” (3050mm) x 60.0” (1525 mm) | 159.44” (4050mm) x 81.10” (2060mm) |

| Maximum Processing Feed Rate | 3937 in/min (100 m/min) | 3937 in/min (100 m/min) |

| Maximum Work Piece Weight | 2094 lbs. (950 kg) | 3637 lbs. (1650 kg) |

| Table Pass Height | 35” (890 mm) | 35” (890mm) |

| Rapid Travel Speed | 6700” (170 m/min) simultaneous | 6700” (170 m/min) simultaneous |

| Positioning Accuracy | 0.0019”/20” (0.05/500 mm) | 0.0019”/20” (0.05/500 mm) |

| Repeatability | ±0.00039” (0.0099 mm) | ±0.00039” (0.0099 mm) |

| Machine Unit Dimensions | 415.0” (10541mm) x 135.0” (3429mm) | 487” (12376mm) x 140” (3560mm) |

| Machine Weight (No Pallet Changer) | 15432 lbs. (7000 kg) | 20943 lbs. (9500 kg) |

| Pallet Changer Weight | 5291 lbs. (2400 kg) | 8900 lbs. (4037 kg) |

| Oscillator Specs | ||

| Manufacturer | Mitsubishi Electric | Mitsubishi Electric |

| Excitation Method | Ytterbium Doped Fiber | Ytterbium Doped Fiber |

| Wavelength | 1.07µm | 1.07µm |

| Available Output Power (CW) | 4 kW , 6 kW, 8 kW, 10 kW | 4 kW , 6 kW, 8 kW, 10 kW |

| Processing Head | Zoom | Zoom |

| Delivery Method | 100µm Fiber Cable | 100µm Fiber Cable |

MAC FUNDING

MAC Funding Corporation is an independent, U.S.-based subsidiary of Mitsubishi Corporation and has been serving the finance needs of the industrial machinery community since 1993. For all Mitsubishi machines, MAC can get you some of the best rates in the industry. Click to learn more —>